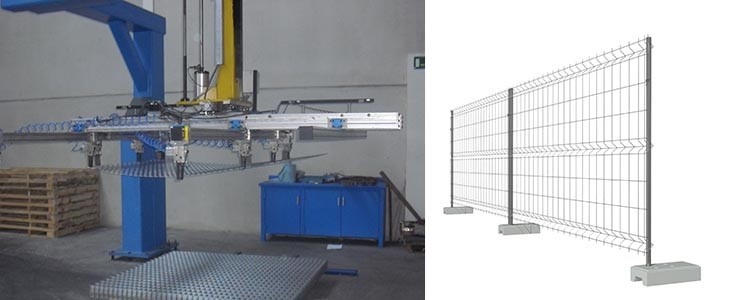

How temporary mobile fences are made

Temporary mobile metal fences are used to safely cordon off hazardous construction sites or outdoor events such as concerts and festivals, to mark the perimeter and help control crowds.

They may not be the most attractive fences, but they are probably one of the most practical.

Manufacturing the mobile fence

It all starts with a giant 7 km reel of galvanized steel wire. A machine called a stretcher unwinds the coil and, as its name suggests, stretches the wire. The wire machine uses an industrial blade to cut off pieces of the length required for manufacturing the fence panels.

In the automatic welding section, a magnetic arm takes the horizontal rods for the panel and places them one by one in position across the vertical rods. Then it begins the welding. This type of welding is called electric welding because a strong electric current is applied to the joins to melt the metal pieces, welding the horizontal rods to the vertical ones. This type of welding is cleaner and faster than traditional welding. In the next process, an automatic press folds the mesh at certain key points. This provides more rigidity and therefore more strength.

In the last step, a round galvanised steel post is placed on each side of the panel and an operator welds these posts to the panels. One at each end of the mesh.

When the time comes to erect the fence, each panel just has to be placed on the concrete feet that sit on the ground.

All components of the temporary mobile fence for building sites are made of galvanised steel, which means that the mobile panel is very strong, maintenance-free and does not rust.